Commercial Adjustable Incline Chest Press Machine 70kg Steel Weight Stack Laser Cut Frame Gym Chest Press Equipment

$2,041.99

Guaranteed Safe Checkout

Features & Compatibility

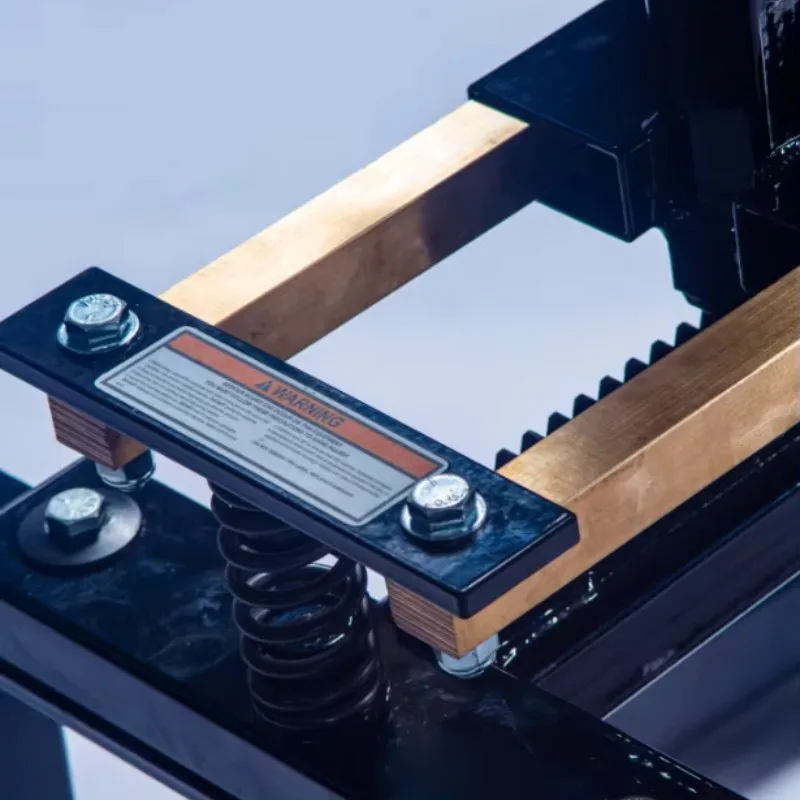

* Heavy-duty steel frame combines φ95mm high-strength round tubes and 50x100mm rectangular steel tubing (3mm thickness),

engineered for high-traffic gym environments.

* 140kg net weight ensures zero vibration during heavy bench pressing.

√ Precision Adjustability

* 7-level sliding seat adjustment (semi-automatic mechanism) for ergonomic alignment across all user heights.

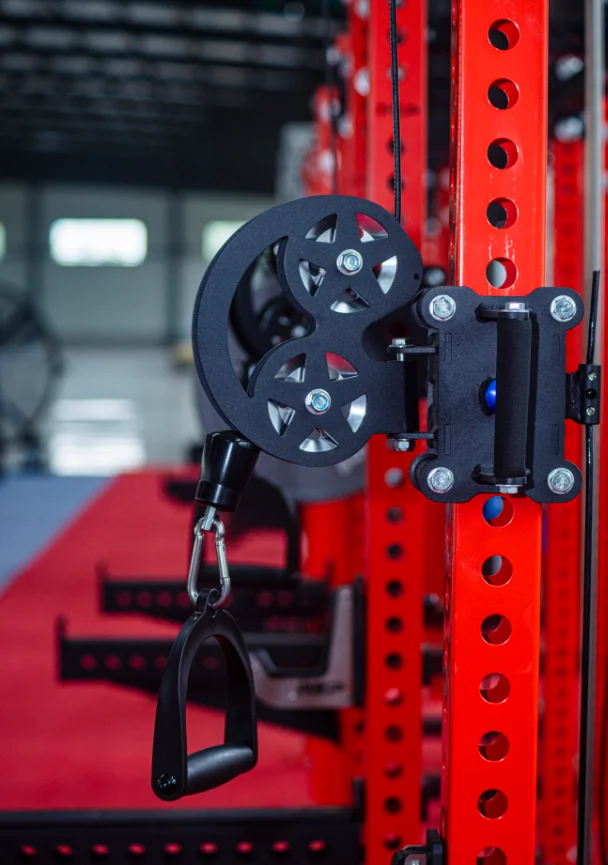

* 70kg steel weight stack with self-lubricating φ5.8mm cables and polished φ20mm corrosion-resistant guide rods.

√ Professional Comfort & Durability

* High-density PU foam padding (1.2mm premium leather) resists deformation under heavy loads; colors: Black/Red/Blue.

* Double-layer anti-corrosion coating: Sandblasting + electrostatic powder spray with glaze finish for scratch/rust resistance.

√ Advanced Manufacturing

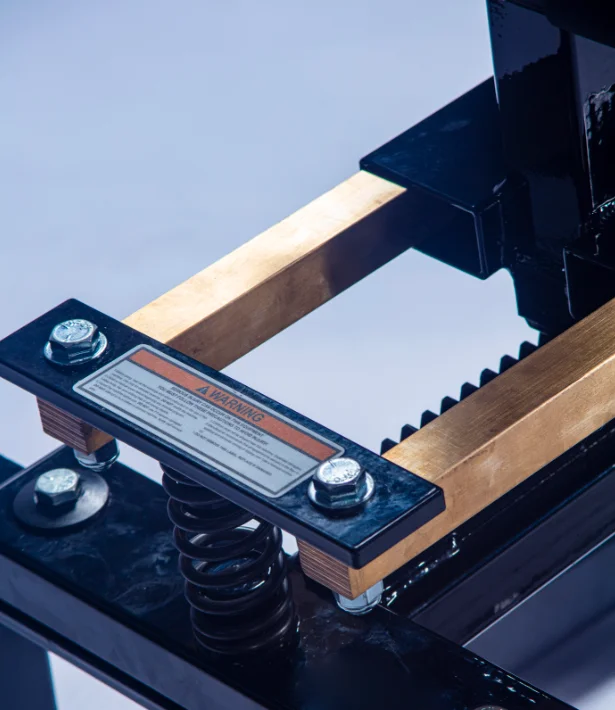

* Laser-cut components and robotic welding ensure ±0.3mm motion accuracy for smooth, consistent pressing paths.

Technical Specifications

* Dimensions: 1460mm (W) x 2170mm (L) x 1620mm (H)

* Frame Material: φ95mm round steel + 50x100mm rectangular steel

* Net Weight: 140kg

* Weight Capacity: 70kg standard steel plates (expandable)

* Cushioning: Triple-layer PU foam with anti-slip stitching

Why Choose Us?

√ Certified Quality & Warranty

* ISO-certified production with 18-step QC checks (tested for 15,000+ reps).

* 5-year frame warranty, 2-year warranty on cables and pulleys.

√ Customizable Solutions

* Optional quick-release weight clamps for circuit training.

* OEM branding available (laser engraving or custom color coatings).

Use Cases

√ Commercial Gyms: Built for 12+ hours daily use; compatible with bumper plates.

√ Strength Training: Targets upper chest and triceps with biomechanically optimized 30-45° incline angles.

√ Home Gyms: Space-efficient design vs. traditional flat/incline/decline combo benches.

Trust-Building Elements

√ Alibaba Verified Supplier with Trade Assurance (98.5% positive feedback).

√ Global Logistics: Rust-proof film + reinforced steel-corner crates (IPPC-certified).

√ Fast Delivery: 25-day production lead time, FOB/CIF/DDP terms supported.

across all production batches.

2,000+ hour salt spray resistance, exceeding EN 13463 commercial fitness equipment standards.

track geometry reduces wear by 63% compared to standard linear systems, validated through 200,000-cycle EN 957-5 endurance

testing.

ultrasonic measurement, achieving <0.01mm micro-movement under 2,000kg dynamic loads. Includes vibration-dampening nylon-insert

locknuts that maintain 98.7% clamping force retention after 50,000 fatigue cycles per ISO 20957-1.

Multi-stage surface engineering meets SAE J2334 corrosion resistance standards:

1. Immersion Pretreatment – 7-tank zinc phosphate conversion coating (MIL-DTL-16232H Type III) achieving 15-20μm crystalline layer

2. Electrophoretic Priming – Cathodic E-coat with ≤1mA/cm² current density for 100% surface coverage

3. Electrostatic Powder Application – Three-layer build:* Base coat: Epoxy-polyester hybrid (80-120μm)

* Mid coat: Polyurethane impact-resistant layer

* Top coat: UV-cured acrylic with 85° gloss retention

4. Ceramic Clear Coat – Nano-SiO₂ reinforced finish (Qualicoat Class 3) delivering:

* 3,500hr salt spray resistance (ASTM B117)

* 9H pencil hardness (ASTM D3363)

* ΔE<1.5 after 2,000hr QUV accelerated weathering

Certified Performance

• ISO 12944 C5-M corrosion classification

• Cross-hatch adhesion Grade 0 (ASTM D3359)

• MEK double-rub resistance >150 cycles

• RoHS-compliant chemistry

✓ Certified Anti-Slip Platform * DIN 51130 Class R12 micro-engraved texture (Ra 3.2μm) * Oil-resistant TPU overlay with >0.85μ slip resistance coefficient

Safety Assurance • EN 20957-5 compliant static/dynamic stability • 4,000kg ultimate load capacity with <0.5° deflection • Electropolished edge radius >0.8mm (ISO 5817 Class C)

✓ Sweat Defense System • ISO 105-E04 compliant perspiration resistance (pH 4.8 acidic / pH 8.0 alkaline) • Antimicrobial additive (EPA 870.3200 registered) inhibits 99.6% bacterial growth • Accelerated wear simulation: 250,000 grip cycles with <5% friction loss

✓ Monolithic RIM Cushion Core polyurethane foam (45±5 Shore A) with 25% rebound resilience (ASTM D3574) Compression-molded in single pour using Reaction Injection Molding (RIM) technology

✓ Premium Contact Surfaces 40,000+ Martindale abrasion cycles (ISO 12947-2) 35N/mm tear strength (ASTM D624) Antimicrobial treatment (AATCC 100 compliant) • 3D-molded PE/PP support shell with 12mm radius edge safety (EN 16139) Certified Performance 150kg dynamic load durability: 100,000 cycles <5% deformation (ISO 7176-8)

✓ Corrosion Defense Technology • Electroless nickel plating (ASTM B733 Type SC, 500hr salt spray) • Multi-axis polishing achieves <0.08μ dynamic friction coefficient • EN 16710-3 chemical resistance against cleaning agents

Engineering Validation * 5,000-cycle dynamic load test: <0.01mm radial runout (EN 957-6) * Concentricity tolerance: 0.03mm TIR over 2m length (DIN 7184) * Accelerated wear simulation: 0.002mm/100km abrasion rate

Certified Performance ▷ 200kN tensile strength (exceeds ISO 6892-1 standard) ▷ -40°C to 120°C operational stability (ASTM E831) ▷ Non-magnetic properties maintained after 10T exposure

Certified Welding Process • EN ISO 3834-2 quality management system implementation

• Continuous parameter monitoring: Quality Assurance Protocols ▷ AWS-certified weld inspector sampling (10% per batch) ▷ Macro-etch testing per ASME IX requirements ▷ Digital weld traceability with QR code tracking

Electrostatic Application Rotary bell atomizers at 65kV charge (Ransburg G1-1000 system) 3-Wet process: Primer/Base/Clear applied in 180s cycle

Certifications • 3,000hr cyclic corrosion testing (GM 9540P) • VOC emissions <35g/m² (EU 2004/42/CE)

✓ Strategic Brand Integration Laser-etched logos with 0.05mm engraving precision (EN ISO 9013)

Additional information

| color |

Black |

|---|

Customer Reviews

Related Products

DH-150 Stability Climatic Temperature and Humidity Test Chamber Lab Environmental Testing Equipment

$8,660.48

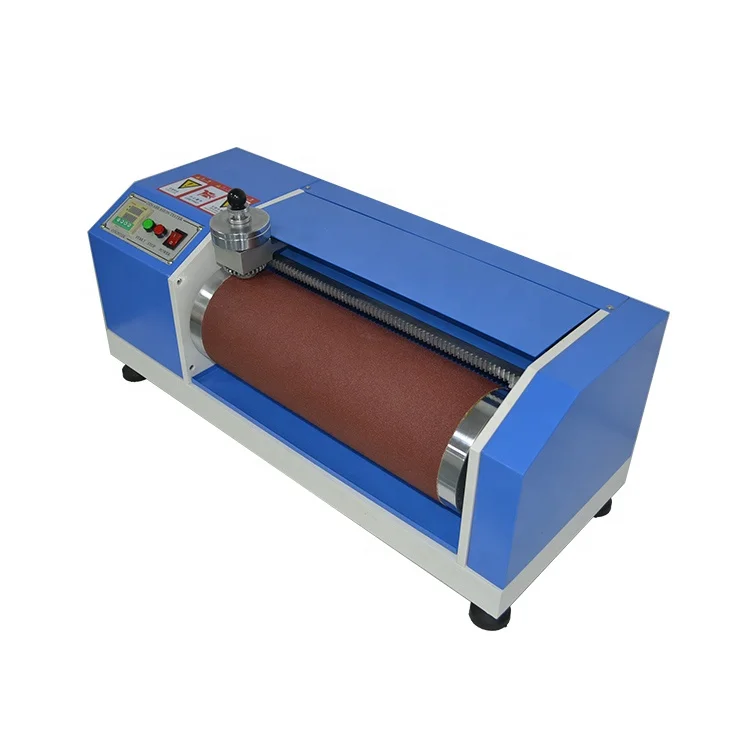

DIN Rubber Abrasion for Lab Wear Tester Footwear Testing Equipment DIN Abrasion Wear Resistance Tester Factory Price

$4,362.20

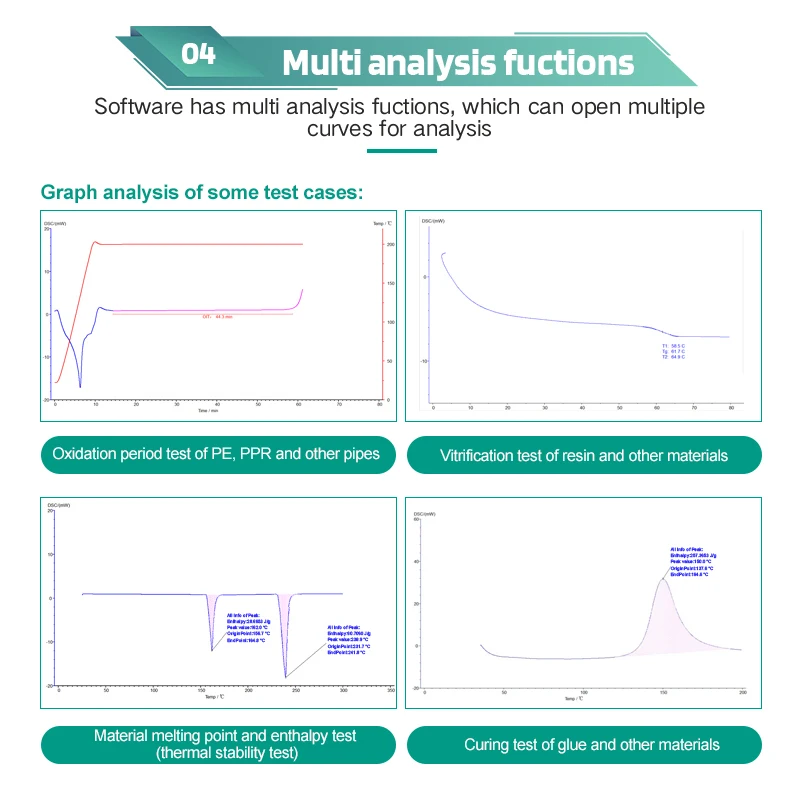

Laboratory Automatic 550C Differential Scanning Calorimetry Oit Oxidative Induction Time Determination Equipment Tester

$15,033.68

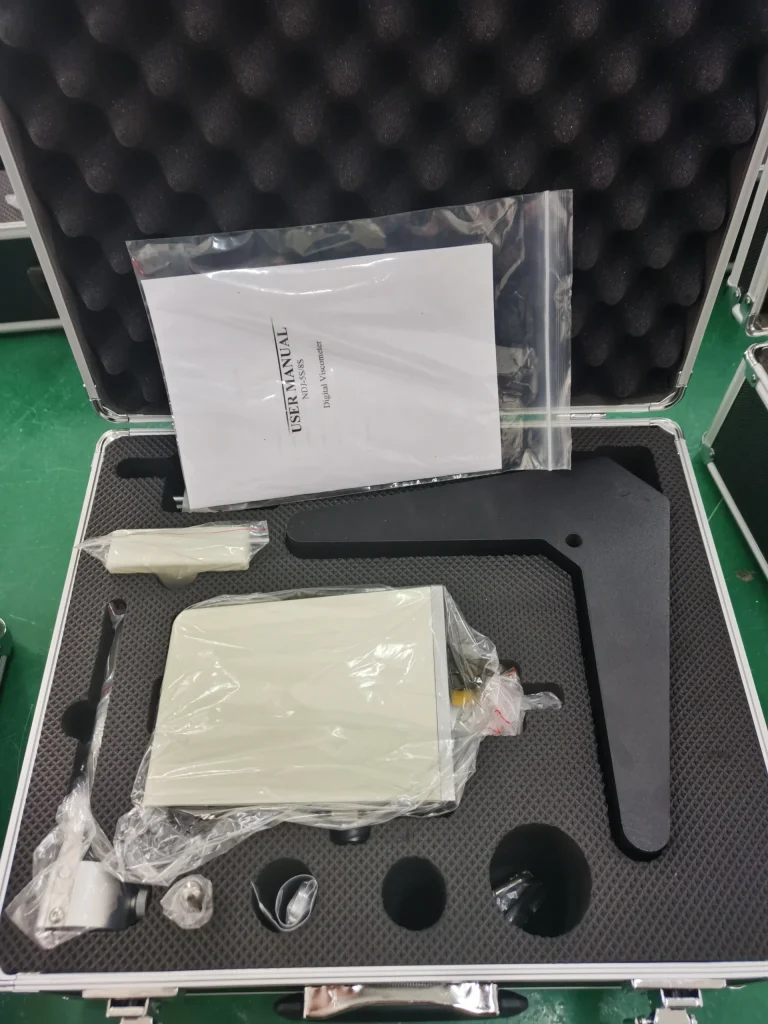

NDJ-8S Digital Rotating Laboratory Equipment Viscometer

$924.80

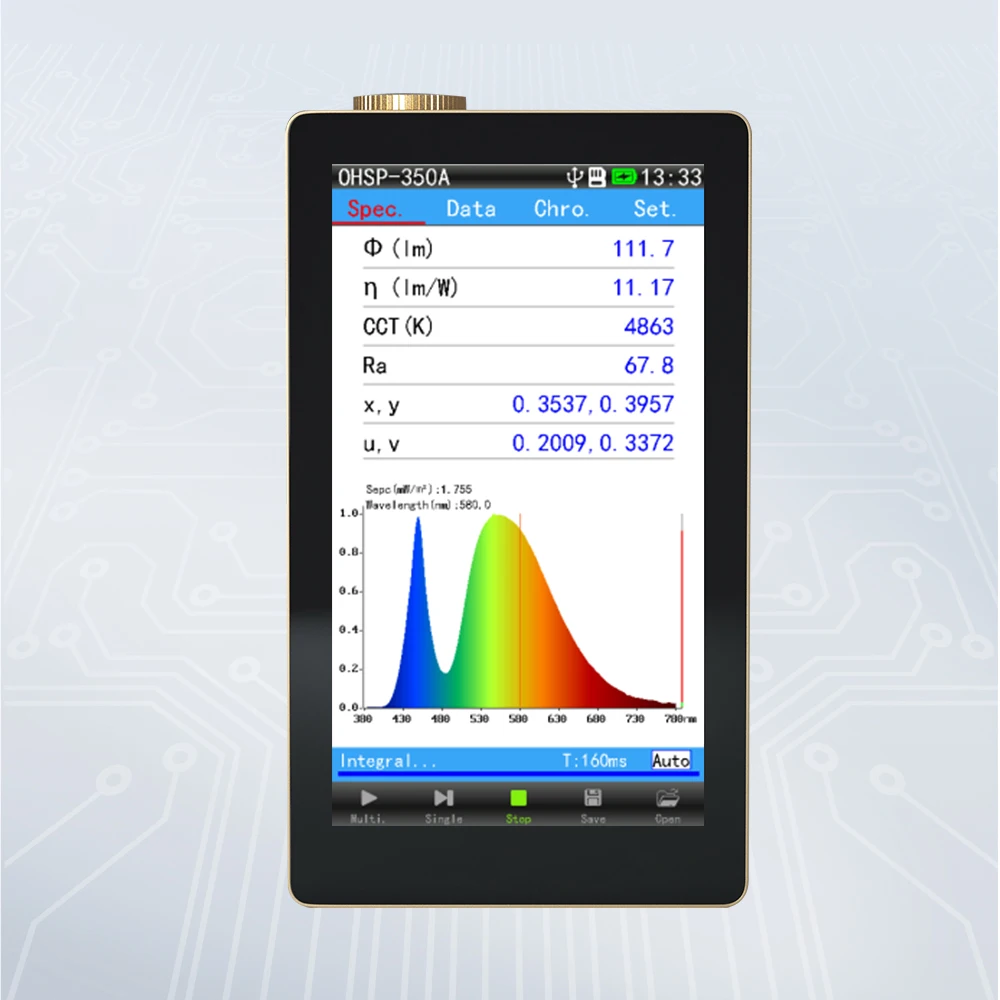

Portable Handheld Spectrometer OHSP350A Laboratory Testing Equipment Usb Brightness Tester

$4,105.80

Reviews

There are no reviews yet.