Segmented Temperature Pressure Air Bubble Removing Machine for Electronics Optoelectronics Industry

$107,823.86

Guaranteed Safe Checkout

Features & Compatibility

Specification

|

Feature 1

|

For Electronics and Optoelectronics industry air bubble removal

|

|

Feature 2

|

segmented high-pressure

|

|

Function 1

|

AutoClave (Removes bubbles) for industrial TFT screen air bubble removal

|

|

Function 2

|

OCF SCA COF Defoaming Remover

|

|

Application 1

|

High temperature max to 80 degree

|

|

Application 2

|

customized industrial TFT screen project

|

|

Voltage

|

380V

|

|

Power

|

8000w

|

|

QC

|

Fully tested before shipping

|

Product Description

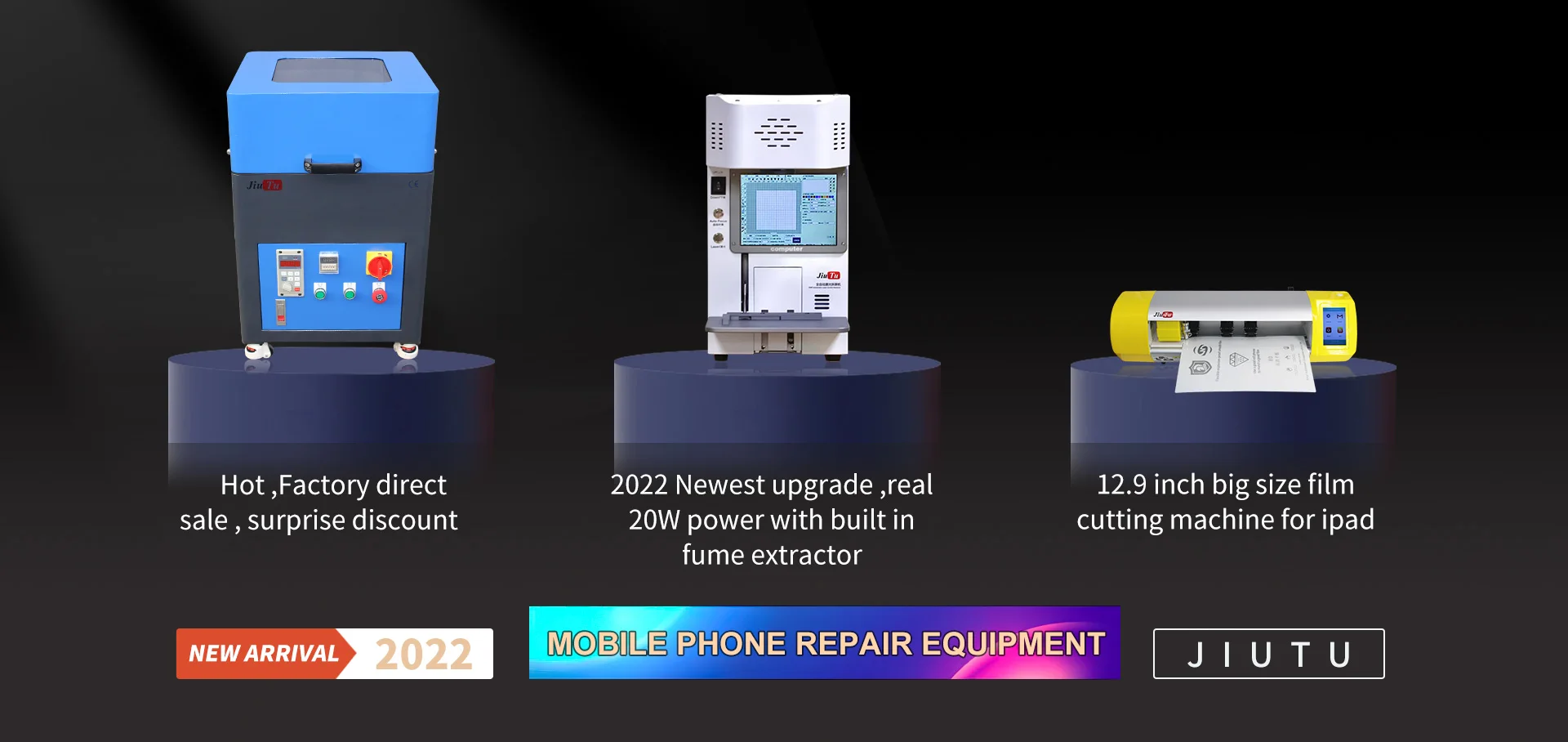

Factory Direct Sale SCA COF OCA LED Large Screen Refurbishment Air Bubble Remover

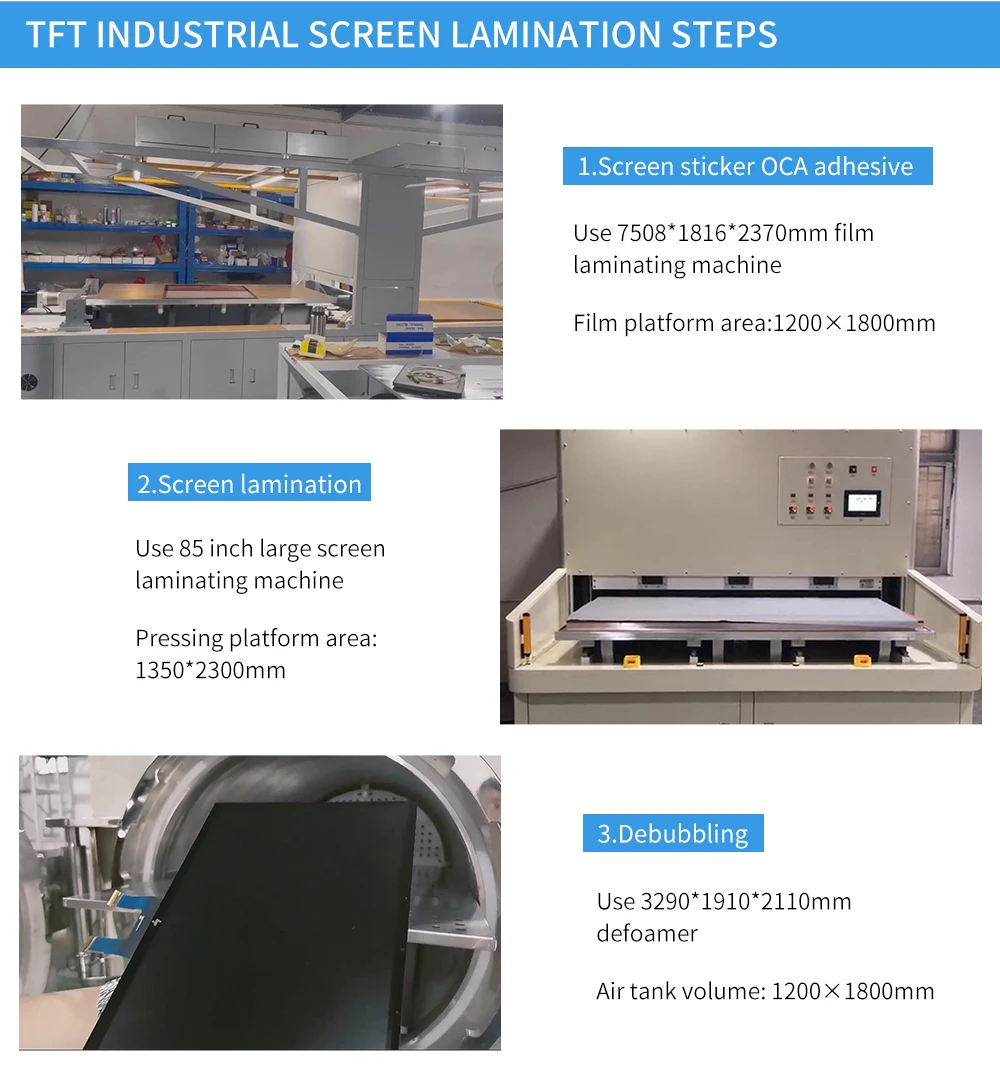

1.1 Equipment introduction and purpose

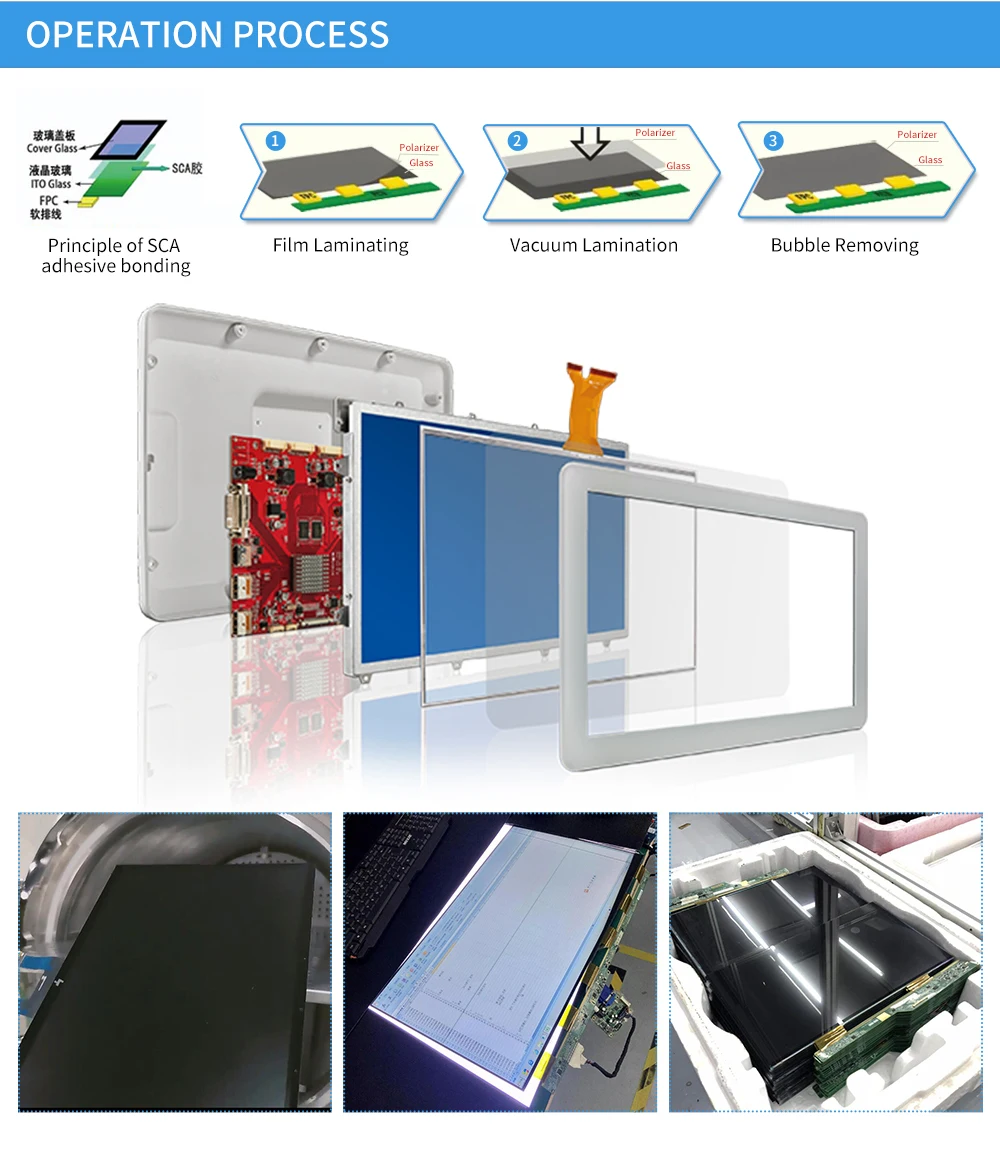

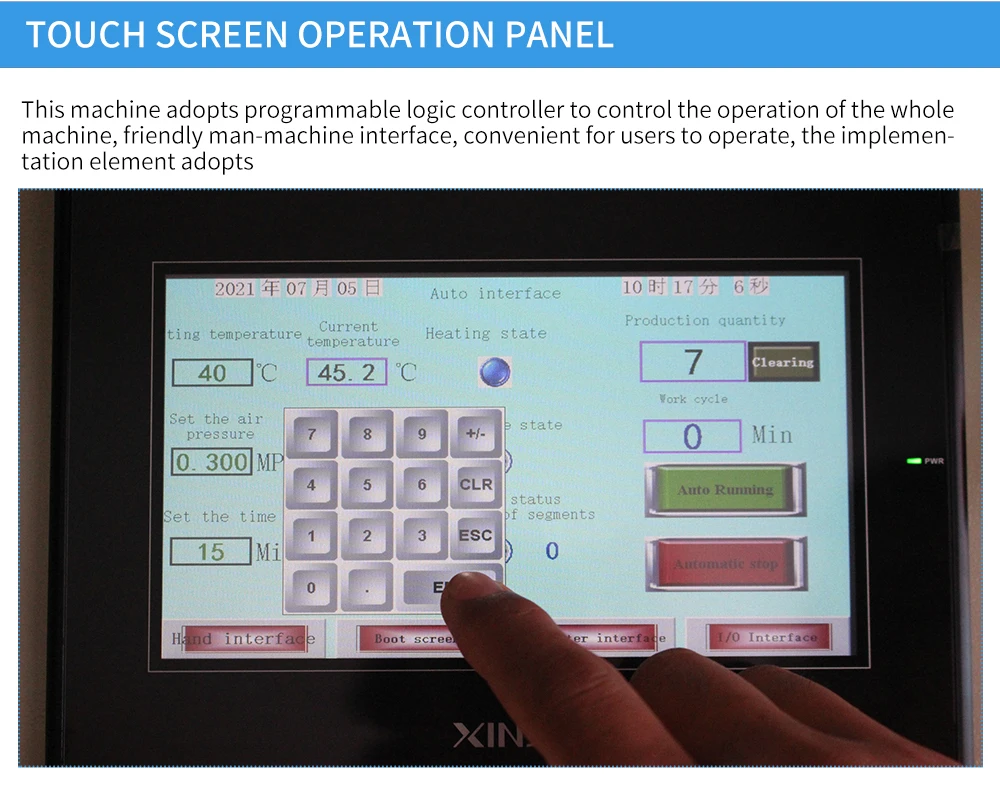

1.1.1 : This equipment is a segmented high-pressure defoaming machine (bubble remover machine).

It’s widely used for electronics and optoelectronics industry, Removing air bubbles and vacuum bubbles

after vacuum lamination with optical glue SCA and OCA glue. Effectively improve product yield.

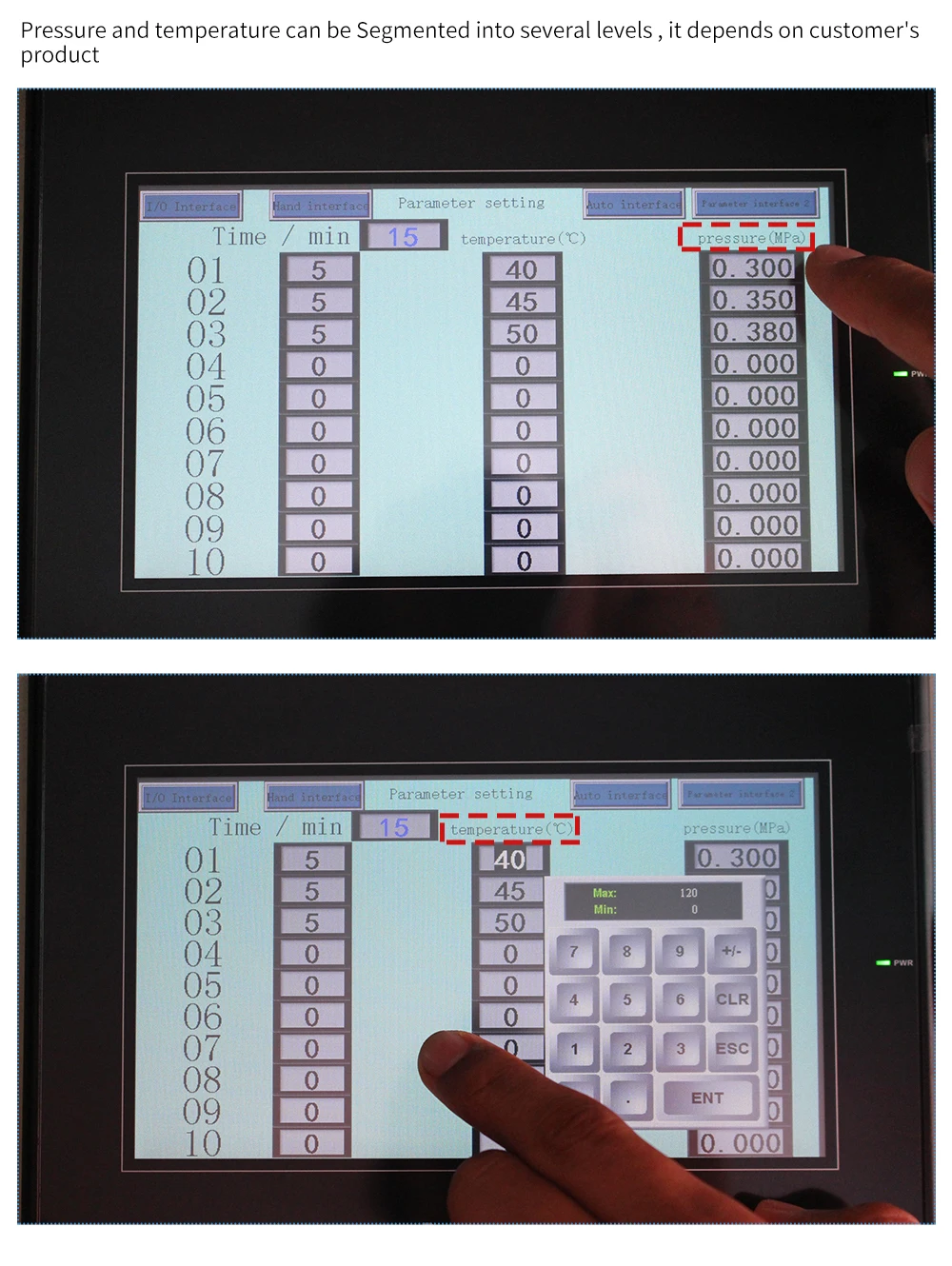

1.1.2 : S

egmented high-pressure , both temperature and pressure can be adjusted by different segmented based on the actual product , max temperature is 80 degree , max pressure is 0.9Mpa

1.2 Equipment technical parameters

1.2.1 machine size :

length 3290mm width 1910mm Height 2110mm

1.2.2 Inner chamber size : Diameter 1200mm Depth 1800mm

1.2.3 Gross weight about 1800KG

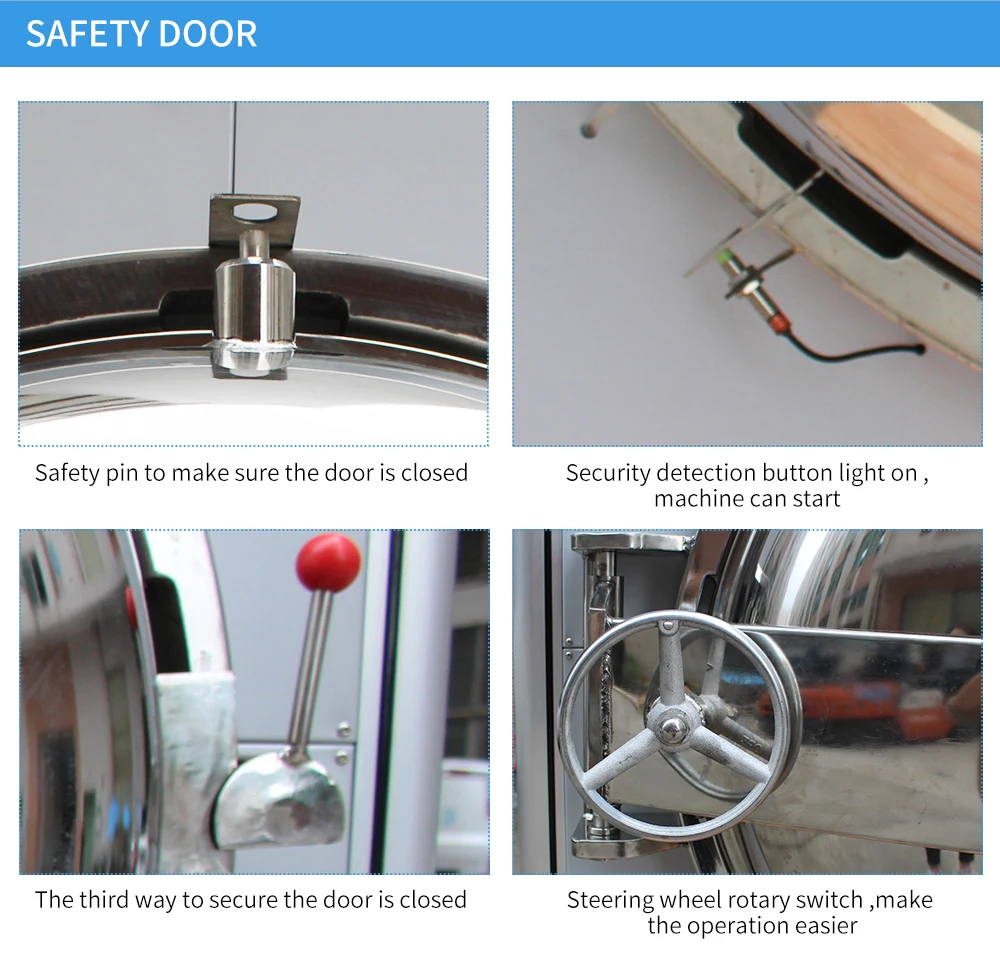

1.2.3 Safety pressure :0.9mpa

1.2.4 Volatge AC 380V

1.3 Equipment Installation

1.4 Equipment maintenance

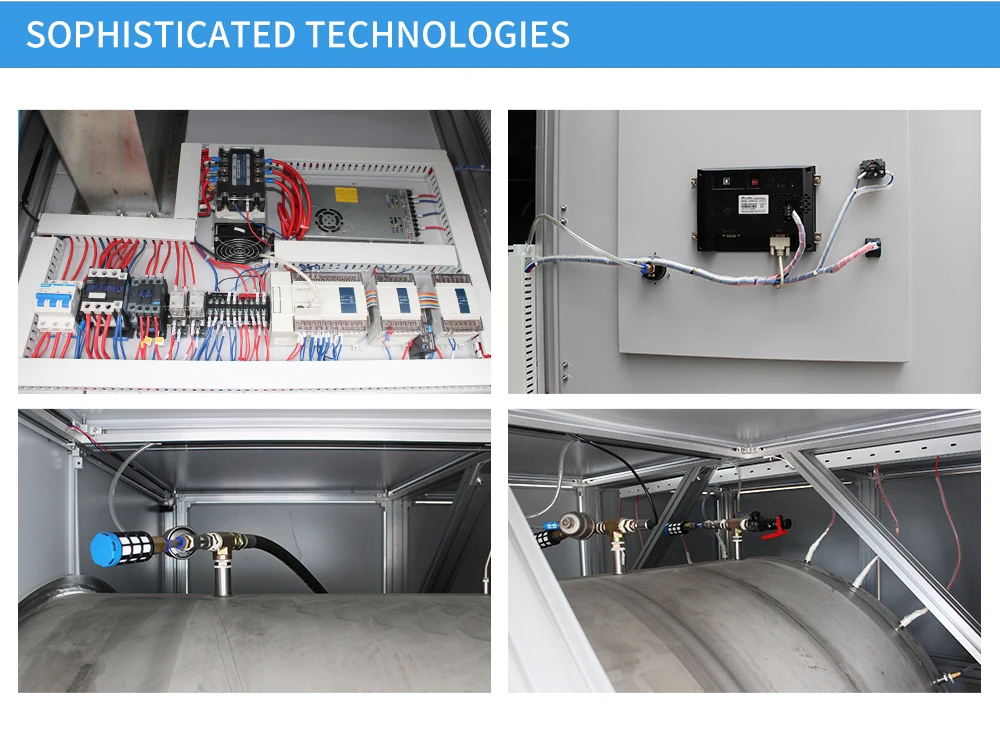

1.4.1 Circuit maintenance: check whether the circuit is loose or abnormal every 15 working days, Appropriate reinforcement if there is any abnormality

1.4.2 Air circuit maintenance; every 15 working days, check the air circuit for air leakage from the air pipe joints.

If there is any abnormality, repair and reinforce or replace it in time

1.4.3 Fan maintenance; manual debugging every 15 working days to check whether the fan is running abnormally, and

replace it in time if there is any abnormality

egmented high-pressure , both temperature and pressure can be adjusted by different segmented based on the actual product , max temperature is 80 degree , max pressure is 0.9Mpa

1.2 Equipment technical parameters

1.2.1 machine size :

length 3290mm width 1910mm Height 2110mm

1.2.2 Inner chamber size : Diameter 1200mm Depth 1800mm

1.2.3 Gross weight about 1800KG

1.2.3 Safety pressure :0.9mpa

1.2.4 Volatge AC 380V

1.3 Equipment Installation

1.3.1 Power supply, to ensure the power supply demand AC380V 8000W.

1.3.2 Air supply to ensure the air pressure supply 0.8mpa.

1.3.3 Machine installation, 12 casters adjust the horizontal state, and the casters are locked and fixed.

1.3.2 Air supply to ensure the air pressure supply 0.8mpa.

1.3.3 Machine installation, 12 casters adjust the horizontal state, and the casters are locked and fixed.

1.4 Equipment maintenance

1.4.1 Circuit maintenance: check whether the circuit is loose or abnormal every 15 working days, Appropriate reinforcement if there is any abnormality

1.4.2 Air circuit maintenance; every 15 working days, check the air circuit for air leakage from the air pipe joints.

If there is any abnormality, repair and reinforce or replace it in time

1.4.3 Fan maintenance; manual debugging every 15 working days to check whether the fan is running abnormally, and

replace it in time if there is any abnormality

1.4.4 Add lubricating oil; manually open the door cover of the defoaming machine every 15 working days and add

lubricating oil to the movable place

lubricating oil to the movable place

Additional information

| model number |

9TU-M061A |

|---|

Customer Reviews

Be the first to review “Segmented Temperature Pressure Air Bubble Removing Machine for Electronics Optoelectronics Industry” Cancel reply

Related Products

Select options

This product has multiple variants. The options may be chosen on the product page

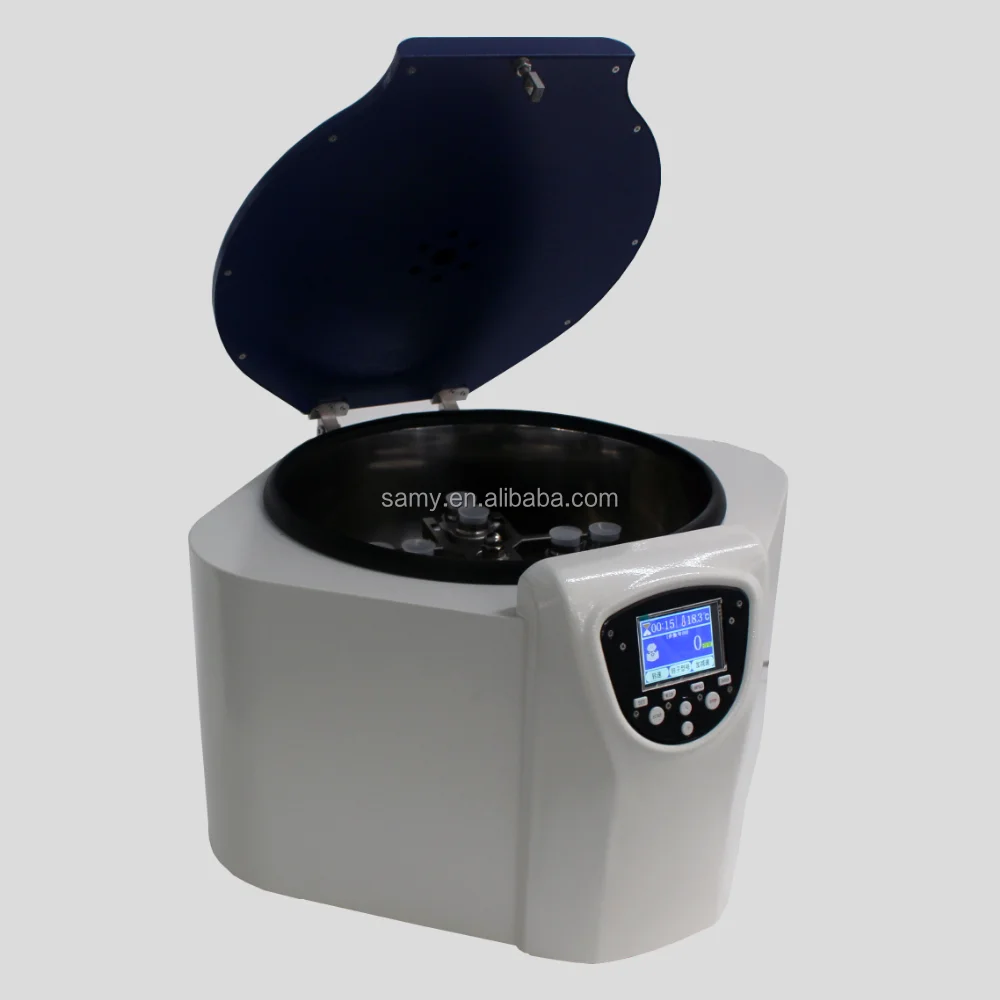

China Professional Manufacture TDZ5-WS Low Speed Bench-top Centrifuge Used for Biocides Separation Lab Equipment

$2,533.85

Select options

This product has multiple variants. The options may be chosen on the product page

DH-150 Stability Climatic Temperature and Humidity Test Chamber Lab Environmental Testing Equipment

$8,660.48

Select options

This product has multiple variants. The options may be chosen on the product page

Hot Sale Glow Wire Combustion Test Equipment Stainless Steel Laboratory Testing Equipment

$4,300.00

Select options

This product has multiple variants. The options may be chosen on the product page

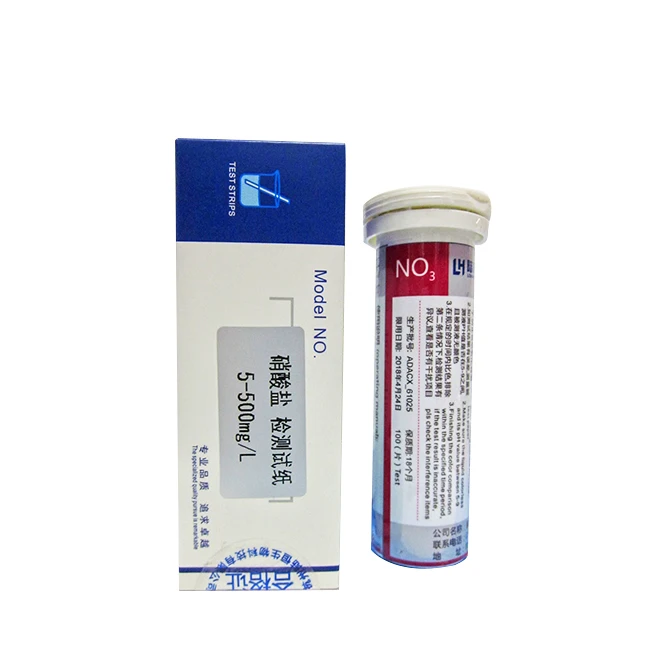

Lohand Rapid Test Series Nitrate Test Paper Laboratory Equipment Water Quality Analysis Bag 100 Strips Packing

$139.79

Select options

This product has multiple variants. The options may be chosen on the product page

NDJ-1 Pointer Rotating Laboratory Equipment Viscometer

$595.49

Select options

This product has multiple variants. The options may be chosen on the product page

Reviews

There are no reviews yet.